Units - The definition of the STL file does not include measurement units.Unless specifically required, Binary is typically preferred due to the smaller file size. Binary / ASCII - While there is a large difference between the encoding of both formats, fundamentally Binary and ASCII are functionally similar, with the caveat that Binary files tend to be far smaller and are handled with less processing power than most slicing software.

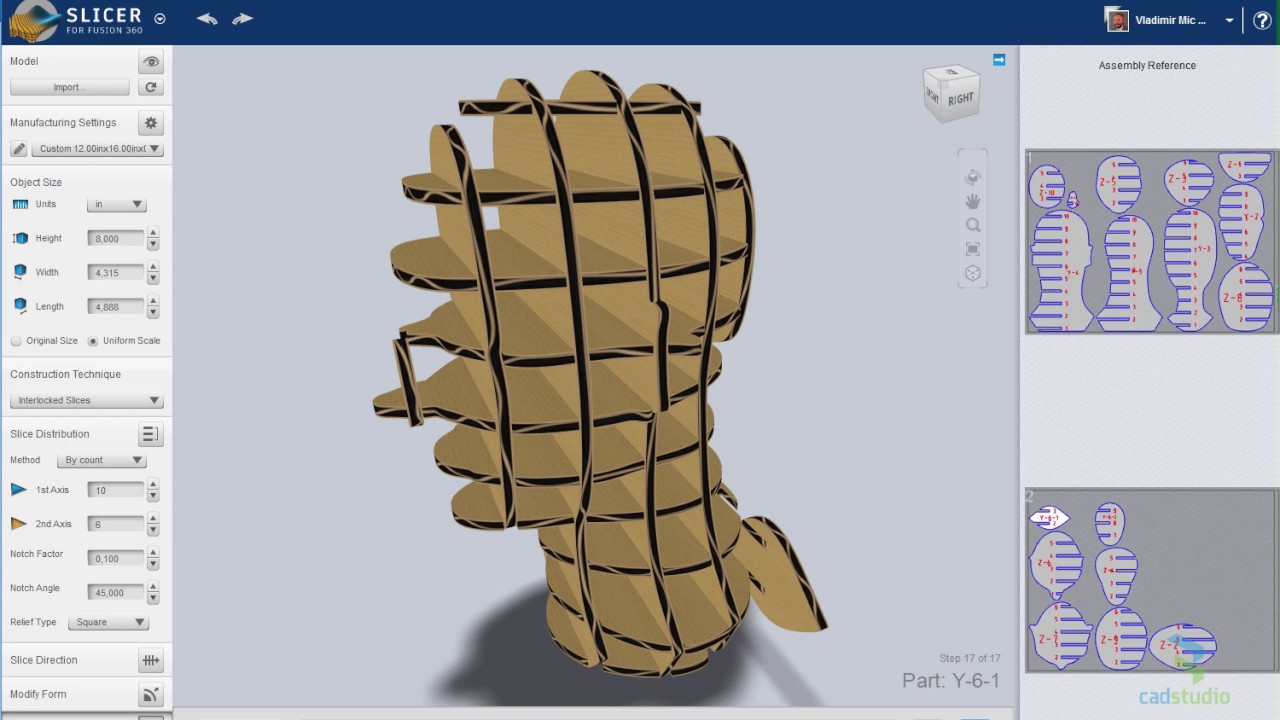

#AUTODESK SLICER FOR MAC SOFTWARE#

While each CAD software has different configuration options and features for exporting STLs, there are a few things that will be common to each solution and are important to pay attention to: Source: Wikipedia, “STL (file format)”, 2019 Converting an STL Examples such as 3DXpert for SolidWorks, Netfabb for Fusion 360, or 3YOURMIND for Siemens NX are add-ons and plugins that remove some of the translation steps, or even allow for direct printing to the printers from the native applications itself.įigure 2: A comparison between native CAD and STL conversion. Outside both requirements of 3D modeling and generation of an STL, there are numerous other “nice-to-haves” that are included in some CAD packages which make preparation for additive manufacturing easier and allow for additional value-add. Generating an STL to match your design is vital to the success of a 3D print, which we’ll cover in more detail below. STL (an abbreviation of “stereolithography”) files are translations/exports of CAD models into triangular surfaces and planes, which are commonly interpreted into G-code, the most widely adopted Computer Aided Manufacturing (CAM) language for automated machine tools. The ability to export native CAD designs into an STL file is required for nearly all 3D printers. An appropriate CAD package will allow you to either parametrically or directly model 3D surfaces, which will allow for easy export into the most common 3D printing file, the STL.

#AUTODESK SLICER FOR MAC FULL#

Some software is specifically designed for prints, drawings, or other 2D designs and lacks the ability to generate full models. The first and most important aspect is the ability to generate 3D models. While most CAD packages will allow for the creation of models to be used in additive manufacturing, there are a few key features and functions that should be confirmed before moving forward with any particular one. Much like traditional manufacturing, additive manufacturing is reliant on computer aided design (CAD) models as the main component of production of the part. As with machining, forging, casting, and stamping, 3D printing starts in the same place - design of the end part.

0 kommentar(er)

0 kommentar(er)